DIGITAL LHD CABLE

Shield Digital

Linear Heat Detection Cable

uses xed temperature detection technology to provide an easy method for

sensing changes in temperature levels. The cable can oer alternative overheat

protection in a vast range of applications and environments, from tunnels, cable

trays, warehousing to sensing changes in temperature within escalators and

other applications where many risks of re are hidden from view.

The digital linear hear detection cable can be directly connected to a

single zone of a conventional fire alarm control panel, or, using an

addressable zone/switch monitor, the digital linear heat detection cable can

easily be interfaced to an addressable loop.

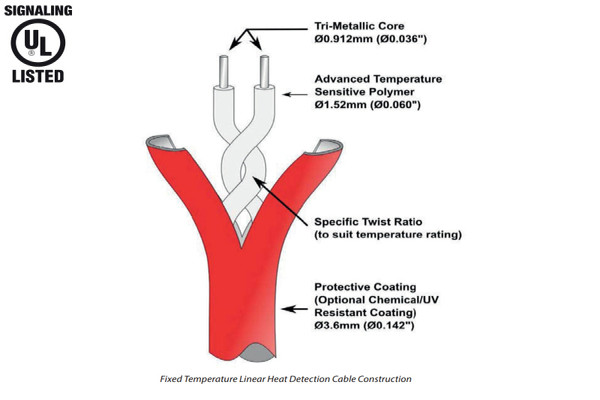

Digital linear heat detection cable is comprised of a pair of twisted low

resistance, tri-metallic conductors, sheathed in advanced temperature sensitive

polymers. When the cable reaches the required temperature the two twisted cores

will fuse together, with a re triggering resistor attached to the input

interface and single core of linear heat cable to activate an alarm at the main

fire panel.

DIGITAL

CONTROL MODULE

A UL864 10th edition approved Digital Control Module is available and

provides additional benefits when used with the Digital LHD cable. It can

simultaneously monitor up to two zones of LHD cable and has separate fault and

alarm outputs for each zone. A built in display shows the state of each zone,

including the distance in meters and feet to the alarm point if an alarm is

triggered. It also includes an RS-485 Modbus RTU output for integration with a

PLC or SCADA system.

FEATURES

- UL 521

Approved.

- CE

Marked.

- Up to

10,000ft (3000m) per zone.

- Detection

along the entire length of sensor cable.

- Optional

Nylon extrusion offering UV protection and increased durability for

outdoor use.

- Optional

Polypropylene extrusion for increased chemical protection in caustic

environments.

- Optional

stainless steel over-braiding for increased mechanical protection.

|

Construction |

Overall insulated, twisted pair of

tri-metallic cores |

|

Insulation |

1kV tested protective outer coat |

|

Additional Insulation Options |

Nylon, Polypropylene or Stainless Steel

braiding |

|

Approvals |

CE Marked, RoHS Compliant, UL |

|

Maximum Zone Length |

3,000m (10,000ft) |

|

Wire Overall Diameter |

3.60mm to 5.08mm (0.142″ to 0.200″) |

|

Minimum bend radius |

50 mm (2″) |

|

Ambient Temperature Range: (dependent upon

action temperature) |

-40°C – 125°C (-40°F – 257°F) |

|

ELECTRICAL |

|

|

Max Voltage Rating |

30Vac, 42Vdc |

|

Resistance |

~100/km (29/kft) per leg |

|

Velocity of Propagation |

~55% |

|

Capacitance |

88 – 150 pF/m (26 – 45 pF/ft) |

|

Inductance |

540 – 1050 nH/m (165 – 320 nH/ft) |