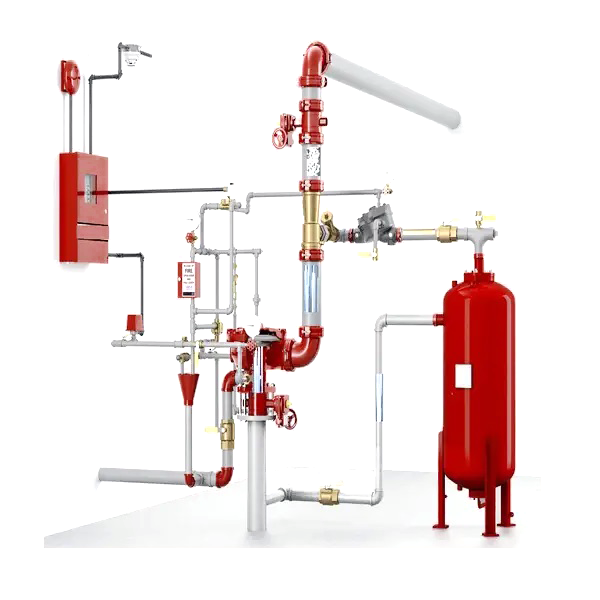

FOAM SUPPRESSION SYSTEM

Fire suppression foam

comprises three parts: foam concentrate, water, and air. When mixed correctly,

these parts form a homogeneous foam blanket that extinguishes flames by the

combined cooling mechanisms, separating the flame source from the product surface,

suppressing vapors, and smothering. This makes foam suppression systems an

effective option for protecting flammable and combustible liquids.

NAFFCO Pre-piped Vertical Bladder Tank is a complete self-contained proportioning

system consisting of a bladder tank, ratio controller, and assembled piping. It

is designed to inject foam concentrate into the water supply of a fire protection

system and automatically proportions over a wide range of flow and pressures

without the use of external power supply. NAFFCO Pre-piped Vertical Bladder

Tank utilize water supply to pressurize the bladder and force the foam concentrate

into the ratio controller. Once the system is in operation, water supply

simultaneously feeds the bladder tank and ratio controller. The water applied

to the outside surface of the bladder will subsequently displace the foam concentrate

contained inside the bladder through the foam outlet pipe and into the metering

orifice of the ratio controller. The water flowing through the ratio controller

will create a low-pressure area between its inlet nozzle and to its downs

stream section. The low-pressure causes the foam concentrate to flow

proportionately to the water flow through the metering orifice. This ensures

correct proportioning of the foam concentrate and water over a wide range of

flow conditions.

TECHNICAL INFORMATION

|

Tank Shell |

Carbon Steel, SA 516 Gr.70. |

|

Bladder |

Vinyl Based Polymer |

|

Pressure Relief Valve (Optional) |

Brass Construction with Set Pressure @ 15

bar |

|

Internal Piping |

Perforated PVC, sch. 80, |

|

Flanges |

ASTM A105, Class 150 |

|

Water Pipe |

Carbon Steel. sch. 40. |

|

Foam Pipes |

Stainless Steel. sch. 40. |

|

Vent/Drain/NRV Valves |

Brass/Bronze. |

|

Sight Glass Valve |

Sight Gauge with Shut Off & Drain Valve |

|

Painting External |

Zinc Rich Primer with Red Enamel Finish |

|

Painting Internal |

Zinc Rich Primer with Coal Tar Epoxy Paint |

DESIGN DATA

|

Tank mounting |

Vertical |

|

Concentrate Storage Capacity |

50-1200 Gallon (see tables) |

|

Flow Range |

78 - 9500 LPM |

|

Foam Concentrate |

AFFF 3%,6% |

|

Design Pressure |

175PSI (12.09 bar) |

|

Test Pressure |

227PSI (15.69 bar) |

|

Ratio Controller Size |

2½”,3", 4” & 6” |

|

Storage Temperature |

+2°C - +49°C |

|

Foam Concentrate Proportioning

Orifice |

3%, 6% |

*NOTE: The UL listing does not include proportioning of 6% Foam Concentrate and 2½" Ratio Controller

RATIO CONTROLLER DETAILS

|

SIZE |

INLET

/ OUTLET FLANGE |

LENGTH (mm) |

ORIFICE

DIA. (mm) |

|

|

3% |

6% |

|||

|

65NB |

ANSI CLASS 150 |

190 |

6.9 |

9.5 |

|

80NB |

266 |

10.7 |

15.04 |

|

|

100NB |

332 |

15.7 |

21 |

|

|

150NB |

342 |

28.7 |

44.5 |

|

RATIO

CONTROLLER SIZE & FLOW RATE

|

SIZE |

FLOW RATE , 3% (as per UL) |

FLOW RATE , 3% (as per FM) |

FLOW RATE, 6% (as per FM) |

|

65NB |

100 - 1550 LPM |

78 - 1036 LPM |

159 - 984 LPM |

|

80NB |

260 - 3000 LPM |

270 - 3000 LPM |

270 - 3000 LPM |

|

100NB |

650 - 6000 LPM |

660 - 5750 LPM |

633 - 3922 LPM |

|

150NB |

1200 - 12000 LPM |

1090 - 9530 LPM |

674 - 4012 LPM |