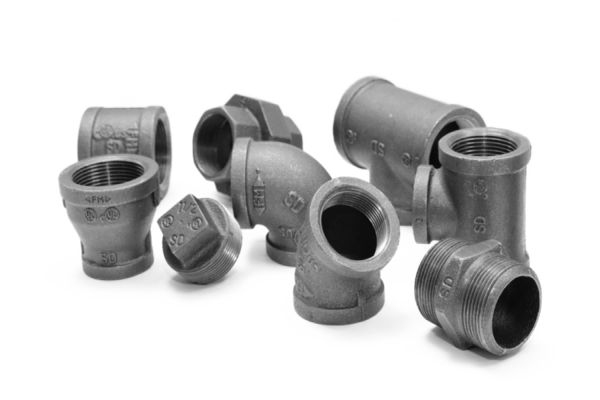

THREADED FITTINGS

SHIELD Threaded Fittings a

certified UL & FM approved. A high quality threaded fittings used to

connect pipes into different sizes for water line as well as fire protection

applications.

Local threaded fittings are also available

Axis Safety Eng. Ltd., specializes in threaded fittings. Threaded fittings are essential components in various industries, such as plumbing, construction, and manufacturing, as they are used to connect and secure pipes and other equipment. If you have any specific questions or need assistance related to threaded fittings or your company's operations, please feel free to ask, and I'll be happy to provide information and guidance.

Threaded fittings are a type of pipe fittings designed with threaded ends that allow them to be easily connected to other threaded pipes or components. They are widely used in various industries for joining and sealing pipes and equipment. Here's some more information about threaded fittings:

Types of Threaded Fittings: Threaded fittings come in various types, including elbows, tees, couplings, unions, bushings, caps, plugs, and crosses. Each type serves a specific purpose in pipe systems.

Materials: Threaded fittings are manufactured from a variety of materials to suit different applications. Common materials include stainless steel, brass, carbon steel, PVC (polyvinyl chloride), and copper. The material choice depends on factors like the type of fluid or gas being transported, environmental conditions, and cost considerations.

Thread Standards: Threaded fittings use different thread standards, depending on the region and application. Some common thread standards include NPT (National Pipe Thread), BSP (British Standard Pipe), and Metric threads. It's crucial to use compatible threads when connecting fittings to pipes or other components.

Sealing: Proper sealing is essential to prevent leaks in threaded connections. Teflon tape (PTFE tape) or pipe dope (thread sealant) is often applied to the threads before assembly to ensure a tight seal. This helps prevent leakage of gases or fluids under pressure.

Pressure Ratings: Threaded fittings are rated for specific pressure levels. It's essential to choose fittings that are suitable for the operating pressure of your system to ensure safety and reliability.

Threaded vs. Welded Connections: Threaded fittings offer the advantage of easy installation and disassembly compared to welded connections. They are particularly useful in applications where frequent maintenance or changes are required.

Applications: Threaded fittings find applications in various industries, including plumbing, HVAC (heating, ventilation, and air conditioning), oil and gas, chemical processing, water treatment, and many others.

Sizes: Threaded fittings are available in a range of sizes to accommodate different pipe diameters and system requirements.

Threaded Flanges: In addition to standard threaded fittings, threaded flanges are used to connect pipes to other equipment, such as valves or pumps. Threaded flanges have a threaded bore and are bolted to the mating equipment.

Threaded Fittings Maintenance: Regular inspection and maintenance of threaded fittings are essential to ensure their integrity and prevent leaks. Over-tightening during installation should be avoided to prevent damage to the threads.

When working with threaded fittings, it's crucial to follow industry standards and best practices to ensure the reliability and safety of your piping systems. Additionally, consulting with experts or engineers who specialize in plumbing or piping systems can help ensure that you choose the right fittings for your specific needs.

Description:

|

Material |

: |

Ductile Iron (ASTM A536, BS EN 1563),

Malleable Iron (BS EN 1562) |

|

Test Pressure |

: |

500 Psi |

|

Applications |

: |

Firefighting, HVAC/Chilled Water |

|

Finishing |

: |

Black, Hot Dipped Galvanised |

|

British Standards - Dimensions |

: |

BS EN 10242, BS 143, BS 1256 |

|

British Standards - Threads |

: |

BS 21, ISO 7/1 (Taper) |

|

American Standards - Dimensions |

: |

ASME B16.3, ASME B16.4, ASME B16.14,

ASME B16.39 |

|

American Standards - Threads |

: |

ANSI B1.20.1 |